More Information

Submitted: 30 December 2019 | Approved: 08 January 2020 | Published: 09 January 2020

How to cite this article: Mehraj N, Agarwal SK, Sinhal R, Abrol K. An evaluation of hardness of commercially available provisional restorative materials: An in vitro study. J Clin Adv Dent. 2020; 4: 001-003.

DOI: 10.29328/journal.jcad.1001013

Copyright License: © 2020 Mehraj N, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Provisional restorations; Hardness; Heat polymerizing acrylic resin

An evaluation of hardness of commercially available provisional restorative materials: An in vitro study

Nimra Mehraj1, Samarth Kumar Agarwal2*, Romil Singhal2 and Kanesha Abrol1

1Post-graduate student, Department of Prosthodontics and Crown & Bridge, Kothiwal Dental College and Research Centre, Moradabad-244001, Uttar Pradesh, India

2Professor, Department of Prosthodontics and Crown & Bridge, Kothiwal Dental College and Research Centre, Moradabad-244001, Uttar Pradesh, India

*Address for Correspondence: Samarth Kumar Agarwal, Professor, Department of Prosthodontics and Crown & Bridge, Kothiwal Dental College and Research Centre, Moradabad-244001, Uttar Pradesh, India, Tel: +9837214936; Email: dr.samarthagarrwal@yahoo.co.in

Statement of problem: Provisional restorations play a critical role in the success of restorative treatment so they must maintain their integrity in the oral environment throughout the diagnostic and restorative phases.

Purpose: The aim of this study was to compare and evaluate the hardness of four different materials used fabrication of interim restoration.

Material and methods: Ten samples with dimensions of 10mmx10mmx2mm were fabricated from four interim materials (DPI, Tempron, Protemp 4 and Transcan). Hardness of samples was measured using Fischer scope hardness tester.

Result: The highest mean hardness was found in Heat polymerizing acrylic resin group. ANOVA test indicated F value to be 2201.01 which was highly significant (p < 0.001).

Conclusion: Heat polymerizing resin and bisacrylics may be considered in a long term provisional fixed prosthesis.

Provisional restorations are an integral part of the treatment planning process and must maintain their integrity throughout the diagnostic and restorative phases [1,2]. These restorations may be needed to function for a long time in oral cavity due to orthodontic or endodontic therapies, temporomandibular joint disorders and during the osseointegration periods of implants. Because of complex environment of oral cavity, they should have certain mechanical properties, such as flexural strength, hardness, and wear resistance [3]. Harder materials should be used since they will have good wear resistance. This reduces the incidence of perforation and plays an important role in maintaining the structural integrity of these restorations for a longer period of time [4]. Understanding the mechanical properties is necessary to evaluate the newer technologies that are coming to the market, verify the manufacturer’s claims and further compared with conventional ones to obtain an optimum material and a suitable technique for long‑term provisional FDPs [5-8]. Therefore, this study makes an attempt to compare and evaluate the hardness of four different materials used fabrication of interim restoration.

The four different types of commercially available provisional restorative materials including autopolymerizing Tempron, heat polymerizing DPI tooth moulding powder, dual polymerizing Protemp 4 and light polymerizing Transcen Temp C&B, were chosen for this study.

Ten specimens of each test material were fabricated using a putty index made from standardized brass mould measuring 10 mm x 10 mm x 2 mm.

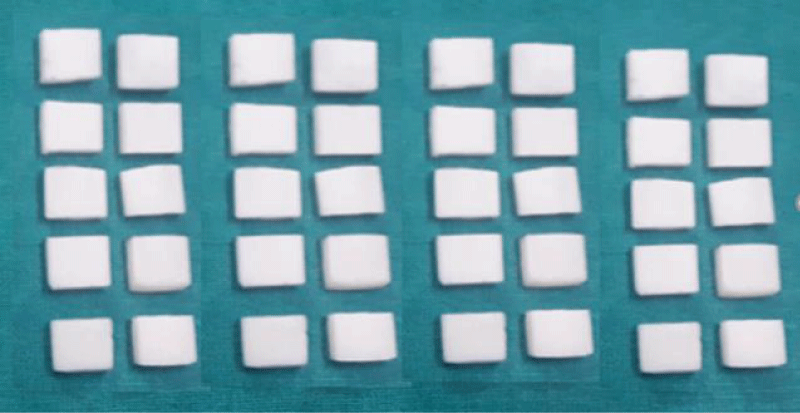

Wax patterns were made using putty index which were then invested in crown and bridge flask. Heat polymerizing samples were then fabricated using standard compression moulding technique and a short curing cycle. Autopolymerised resin monomer and polymer were mixed according to manufacturer’s instructions (powder/liquid ratio of 1.0g/0.5mL) and packed into prepared index followed by smoothening with cellophane sheet. Protemp 4 resin was dispensed into the putty index using auto mixing device, smoothened with cellophane sheet, retrieved from index after 5 minutes and then cured using LED curing light. Light cure composite resin was removed from the stick of light cure material with plastic spatula, kneaded with fingers, pressed into the putty index and smoothened with the cellophane sheet. The samples were then cured with LED curing light for 30 seconds. All 40 specimens were finished with a carbide bur and 600 grit silicon carbide papers, and checked by a Vernier caliper for accurate dimensions (Figure 1).

Figure 1: Finished samples.

All the specimens were immersed in distilled water for 24 hours and thereafter, tested for hardness on Fischer scope HM 2000.

Result showed that the highest mean hardness was found in Heat cured acrylic resin group, while light cured composite resin group exhibited the lowest mean hardness (Table 1).

| Table 1: Descriptive statistics of Vickers hardness among various groups. | |||

| N | Mean | SD | |

| Group A | 10 | 8.20 | 0.297 |

| Group B | 10 | 14.98 | 0.258 |

| Group C | 10 | 14.13 | 0.366 |

| Group D | 10 | 5.43 | 0.315 |

Analysis of variance of hardness in different groups showed F value to be 2201.01 which was highly significant (p < 0.001) (Table 2).

| Table 2: ANOVA for hardness among various groups | |||||

| Sum of Squares | df | Mean Square | f - value | p - value | |

| Between Groups | 640.8 | 3 | 213.59 | 2201.01 | < 0.001* |

| Within Groups | 3.5 | 36 | 0.100 | ||

| Total | 644.3 | 39 | |||

In intergroup comparisons, least significant difference test was performed. Heat polymerizing acrylic resin showed significantly higher mean hardness as compared to autopolymerized cold cure acrylic resin and light cured composite resin (p < 0.001). Difference between Heats cured acrylic resin and protemp 4 was not statistically significant (p > 0.078). On comparison with auto-polymerized cold cured acrylic resin, Heat Cure acrylic resin and Protemp 4, light cured composite resin showed lower mean flexural strength values, which was highly significant (p < 0.001) (Table 3).

| Table 3: intergroup comparison based on Vickers hardness among various groups. | ||

| Group comparison | Mean difference | p - value |

| A vs. B | -6.78 | < 0.001* |

| A vs. C | -5.93 | < 0.001* |

| A vs.D | 2.77 | < 0.001* |

| B vs. C | 0.85 | 0.078 |

| B vs.D | 9.55 | < 0.001* |

| C vs. D | 8.70 | < 0.001* |

When an interim restoration is fabricated with a material having good wear resistance, the risk of perforation is decreased and it maintains its structural integrity for a longer period of time [4]. There are several types of hardness tests available and in this study Vickers hardness test was determined which is based on the ability of the surface of any material to resist the penetration of a specific tip with a given load for a specific time [9].

Results in table 2 indicated that mean hardness of heat polymerising DPI was highest and was similar to dual cure Protemp. This was followed by auto polymerising Tempron and least was seen with visible light cure Transcan temp C&B. The differences between groups were significant (p < 0.05). Similar observations were made by Jo, et al. [4]. It is believed that differences arise from variations in the chemical structure of the material and partly due to the process of polymerisation [4,5,10-12]. The possible factors responsible for the higher hardness of heat cure material can be its high molecular weight and the cross-linked polymer structure, which makes it less polar, leading to a decrease in the rate of water absorption [13]. Heat polymerization also eliminates excess residual monomer (0.2% – 0.5%), leading to a higher degree of polymerization and therefore makes the material stronger [4]. The data indicated that Protemp 4 has comparable hardness to heat cure acrylic resin and the possible reason could be that it contains dimethacrylate polymer and bis-GMA resins with fillers and stabilizers and bis-acryls have a rigid central structure that reduces the dissolution of the resin-filler particles [7]. Conventional methacrylate resins are mono-functional, low molecular weight and linear molecules that exhibit decreased strength and rigidity. In addition, if they are not polymerized under pressure, air bubbles will be trapped and decrease their strength [5]. Least hardness values of light cure composite (Transcen Temp C&B) is attributed to the lesser filler content as compared to normal composites [4].

Within the limitations of this study, it may be concluded from that:-

1. Heat Cured acrylic resin and Protemp 4 showed maximum hardness among all the tested materials.

2. Light cured composite resin showed minimum hardness among all tested materials.

3. The sequence of mean hardness in decreasing order is as follows:- Heat cured acrylic resin = Protemp 4 > Auto-polymerized cold cured acrylic resin > Light cure composite resin.

Heat polymerizing resin and bisacrylics may be considered in a long term provisional fixed prosthesis.

- Rosenstiel S, Fujimoto J, Land MF. Contemporary fixed prosthodontics. 4rd ed. St. Louis: Missouri. 2007; 466.

- Diaz-Arnold AM, Dunne JT, Jones AH. Microhardness of provisional fixed prosthodontic materials. J Prosthet Dent. 1999; 82: 525-528. PubMed: https://www.ncbi.nlm.nih.gov/pubmed/10559723

- Savabi O, Nejatidanesh F, Fathi MH, Navabi AA, Savabi G. Evaluation of hardness and wear resistance of interim restorative materials. Dent Res J. 2013; 10: 184-189. PubMed: https://www.ncbi.nlm.nih.gov/pubmed/23946734

- Jo LJ, Shenoy KK, Shetty S. Flexural strength and hardness of resins for interim fixed partial dentures. Indian J Dent Res. 2011; 22: 71-76. PubMed: https://www.ncbi.nlm.nih.gov/pubmed/21525681

- Digholkar S, Madhav V, Palaskar J. Evaluation of the flexural strength and microhardness of provisional crown and bridge materials fabricated by different methods. J Indian Prosthodont Soc. 2016; 16: 328-334. PubMed: https://www.ncbi.nlm.nih.gov/pubmed/27746595

- Khanna G, Aparna IN. Comparison of microhardness of three different types of acrylic artificial denture teeth: An in vitro study. J Orofac Res. 2013; 3: 181-185.

- Anusavice KJ. editor. Phillip’s science of dental materials. 11th ed. St Louis: Missouri. 2003; 96-98.

- Craig RG. Restorative dental materials. 8th ed. St Louis: Mosby. 1989; 103.

- Pereddy MR, Janani S, Gupta B. Comparative evaluation of hardness of four provisional restorative materials: An in vitro study. Eur J Prosthodont. 2016; 4: 51-55.

- Akova T, Ozkomur A, Uysal H. Effect of food-simulating liquids on the mechanical properties of provisional restorative materials. Dent Mater. 2006; 22: 1130-1134. PubMed: https://www.ncbi.nlm.nih.gov/pubmed/16386787

- Yap AUJ, Mah MKS, Lye CPW, Loh PL. Influence of dietary simulating solvents on the hardness of provisional restorative materials. Dent Mater. 2004; 20: 370-376. PubMed: https://www.ncbi.nlm.nih.gov/pubmed/15019452

- Pasha KSA, Bhatia S, Pandav G. An in- vitro study to compare and evaluate the hardness of various commercially available provisional restorative materials. IP Ann Prosthodon Restor Dent. 2018; 4: 44-46.

- Dixon DL, Fincher M, Breeding LC, Mueninghoff LA. Mechanical properties of light-polymerizing provisional restorative material with and without reinforcement fibers. J Prosthet Dent. 1995; 73: 510-514. PubMed: https://www.ncbi.nlm.nih.gov/pubmed/11791260